In the past the boats were built from the wood. Nowadays the wood have been largely superseded by GRP (Glass Reinforced Plastic). The Nauticat however holds on the wood craftsmanship as the yachts interior is built by using the traditional woodworking techniques. The manual building process enables that every Nauticat can be manufactured according to buyers wishes.

Eve’s grandfather was a real old time carpenter. When grandpa built houses, Eve’s playhouse or dollhouse complete with miniature furniture he always said that “workmanship must be done in a way that I dear to say its done by me and that corners and joints must always be fully aligned”.

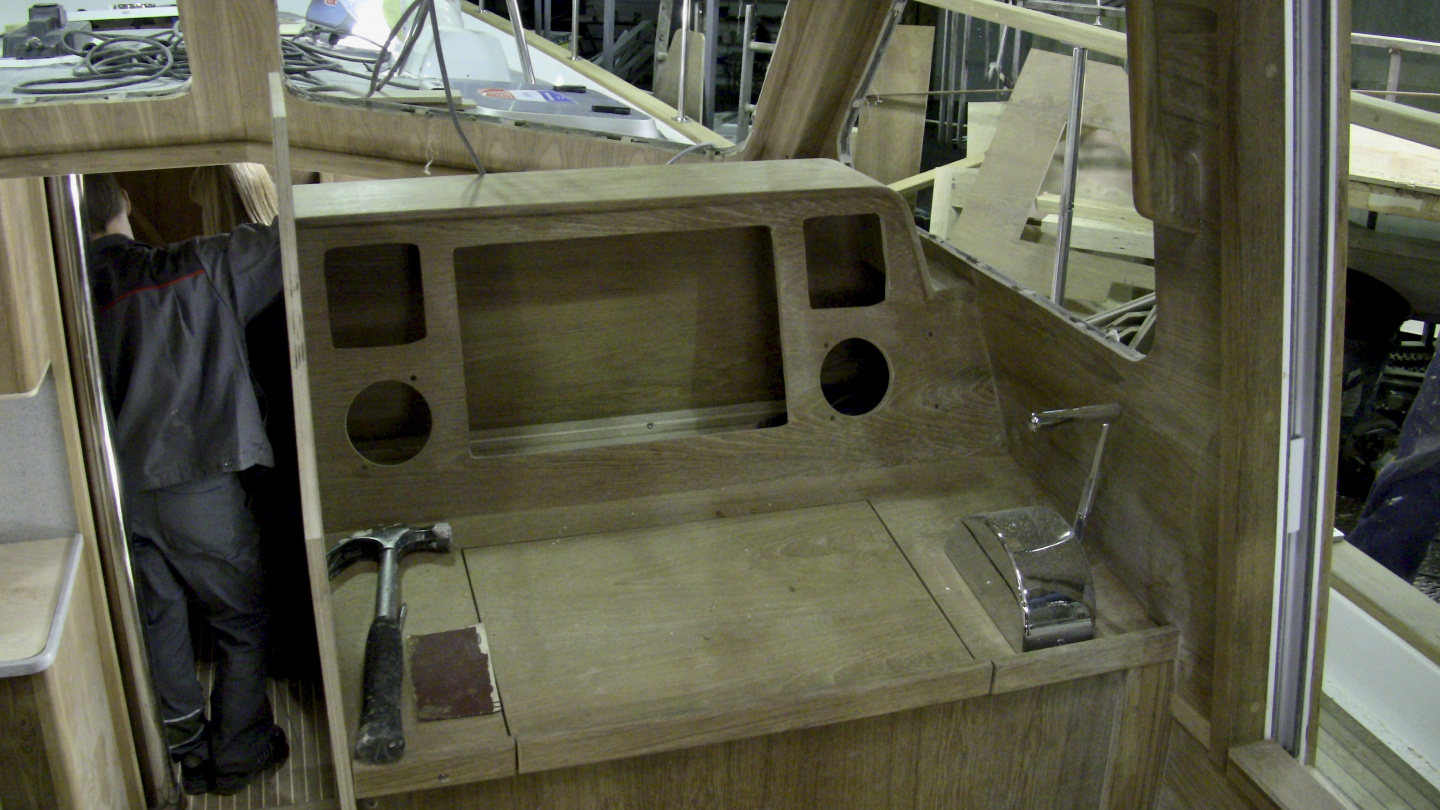

So it was a pleasure to watch the work of Nauticat carpenters. Yachts interior is built from floor upwards maintaining the horizontal and vertical alignment. This makes that corners of cabinets and all joints are always straight. In addition the craftsmanship can be seen in good visual design in all wooden parts. After all it is quite a challenge in boat-building to connect the curvy three-dimensional boat lines into sleek outcome. A good example of this is when we were wondering about wide margin space on upper part of the kitchen cupboard. We received a prompt answer that if the margin would be narrower it would not be on line with port side ceiling and other cabinets because of rooftop curving.

The boatyard gives free hands to customers and of course the customers ask for all kind of things. We enjoyed working with master carpenter Perttu. We told him what we are looking for and Perttu’s implementation usually exceeded our expectations. For example during our visit to the yard we discussed about the location of TV. We did not want to locate the TV inside the wall of the cabinet as it is done usually. We proposed a simple fixture on the wall. However during next visit Perttu had made a mockup of the TV and a rotating fixture that can be turned against the wall and fixed there when on sea. This is only one example where the yard made more than we expected.

Because of hand made woodworking the customer can choose the boats interior layout as the locations of the cabin walls can be moved around. E.g. some customers have opted for a Finnish sauna in aft. We wanted a separate head and shower with the spacious aft cabin. Also the size and location of cabinets can be decided by customer. We will have large cabinets on both side of the bed with a lot of storage space.

Accordingly a location and size of the galley can be tailored according to intended use. We have seen both U- and L-shaped kitchens in different sizes and locations onboard. Our boat is built in a way that galley can be used for cooking also on sea and the boat is suitable for living aboard for longer times.

We will have doors on all cupboards because we did not want to have any open shelfs to gather the dust. Also heavy seas can make things to fall out from open shelfs. The carpenters built all cabinets according to the measurements we wished for. Even the number and height of the shelves in the cabinets can be decided depending on the needs of the customer. We have one special cabinet between forward head and guest cabin on the port side for our foldable tandem. The cabinet is built according to the measurement of the bike.

Woodwork lasted several weeks during which all the floors, walls, cabinets, tables, beds and other things are built. When everything was ready all teak surfaces inside were varnished. After the varnish was dry all surfaces and edges were protected with plywood and carton as the next phase is the equipment installation and after that the boat will be fully rigged and tested in test pool before the delivery.